Pipeline systems form the backbone of many critical industries, including petrochemical, power generation, steel manufacturing, shipbuilding, and ocean engineering. Ensuring the safe and reliable operation of these pipelines is paramount, as any failure or incorrect operation can result in catastrophic accidents, environmental hazards, or significant financial losses. Among the various safety measures employed, mechanical valve interlocks have emerged as an essential tool to enhance pipeline safety by preventing improper valve operation and enforcing strict operational protocols.

Nudango, a professional provider of industrial safety solutions, has established a strong reputation in the field. The company holds CE, HSE, and other system certifications and offers a wide range of products, including valve interlocks, trapped key interlocking systems, remote and portable valve actuators, and valve position indicators. These products are widely adopted both domestically and internationally, providing reliable solutions for industries where pipeline safety is critical.

Understanding Mechanical Valve Interlocks

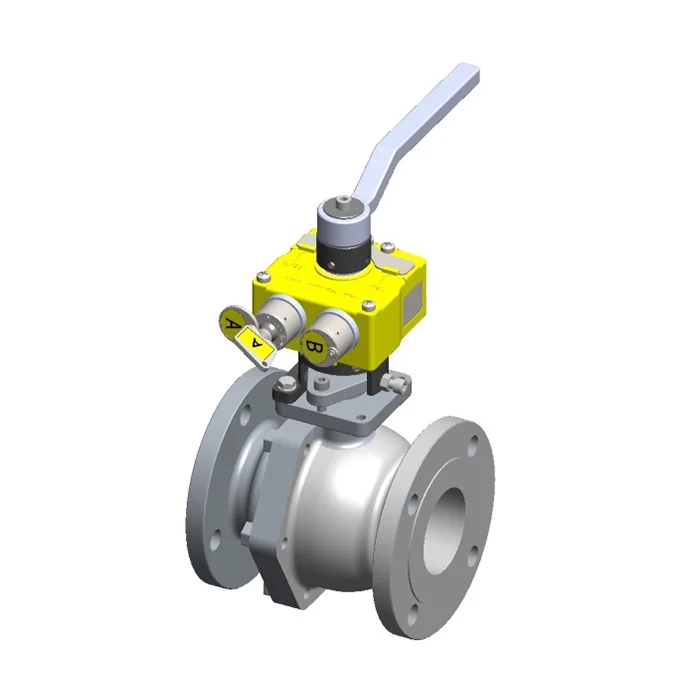

Mechanical valve interlocks are physical devices designed to enforce the correct sequence of valve operations. Unlike electronic or software-based safety controls, mechanical interlocks provide a fail-safe mechanism that physically prevents unsafe actions. They are particularly effective in preventing human error, which remains one of the leading causes of pipeline incidents.

There are several types of mechanical valve interlocks commonly used in industrial pipelines:

-

Trapped Key Interlocking Systems: These systems use keys to control the operation of valves. A key must be inserted or removed in a specific order to operate a valve, ensuring that the sequence of operations is strictly followed.

-

Remote Valve Actuators: These allow operators to control valves from a distance, reducing exposure to hazardous environments while maintaining operational safety.

-

Portable Valve Actuators: These devices provide flexibility for maintenance and emergency operations, enabling safe valve manipulation without direct manual handling.

-

Valve Position Indicators: These indicators provide visual confirmation of a valve’s status, which is critical for operators managing complex pipeline networks.

By combining these devices, industries can create comprehensive safety systems that minimize risks associated with improper valve operations.

Key Considerations for Pipeline Safety

When implementing mechanical valve interlocks in pipeline systems, several critical considerations must be taken into account to ensure maximum effectiveness:

-

Compliance with Safety Standards

Pipelines are subject to strict safety regulations. Mechanical valve interlocks must comply with international and local standards, including CE, HSE, and ISO certifications. Nudango’s products, for instance, meet these requirements, offering clients confidence that their safety systems adhere to recognized regulatory frameworks. -

System Design and Sequencing

Proper sequencing of valve operations is essential in preventing accidents such as overpressure, backflow, or chemical mixing errors. Mechanical interlocks must be carefully designed to enforce the correct sequence, ensuring that critical steps cannot be bypassed. Collaboration with experienced providers like Nudango ensures that interlock systems are tailored to the specific operational logic of each pipeline network. -

Material and Environmental Suitability

Pipelines often operate in harsh conditions, including high pressure, extreme temperatures, or corrosive environments. Selecting interlocks made from durable, corrosion-resistant materials is crucial for long-term reliability. Nudango’s products utilize high-quality materials designed to withstand the challenging conditions found in petrochemical plants, shipyards, and offshore installations. -

Ease of Operation and Maintenance

While safety is paramount, interlocks should also be user-friendly. Operators must be able to manipulate valves efficiently without complex procedures, and maintenance staff should have clear access for inspection and servicing. Portable and remote actuators, as provided by Nudango, offer practical solutions that enhance operational efficiency while maintaining safety. -

Integration with Existing Systems

Many industrial facilities operate complex pipeline networks with existing safety and automation systems. Mechanical valve interlocks must integrate seamlessly with these systems, including SCADA (Supervisory Control and Data Acquisition) and other monitoring platforms. Nudango’s remote valve actuators and valve position indicators facilitate such integration, allowing operators to monitor and control valve operations effectively. -

Redundancy and Fail-Safe Design

In critical pipelines, failure is not an option. Mechanical interlocks should include fail-safe mechanisms that prevent unsafe operations even in the event of a component malfunction. Trapped key systems inherently provide redundancy, as the physical key cannot be bypassed, ensuring that the operational sequence is maintained under all circumstances. -

Training and Operational Protocols

The effectiveness of mechanical valve interlocks depends not only on the hardware but also on the competency of personnel. Comprehensive training programs should be implemented to ensure that operators understand the correct procedures, the purpose of the interlocks, and emergency protocols. Providers like Nudango often offer technical guidance and support to ensure proper training and implementation.

Benefits of Mechanical Valve Interlocks in Pipeline Operations

The adoption of mechanical valve interlocks offers a range of benefits for pipeline safety:

-

Enhanced Safety: By preventing incorrect valve operation, interlocks significantly reduce the risk of accidents and incidents.

-

Operational Consistency: Enforcing correct sequences ensures smooth and predictable pipeline operations, minimizing process disruptions.

-

Regulatory Compliance: Properly implemented interlocks help facilities meet stringent safety regulations, avoiding penalties and enhancing corporate reputation.

-

Reduced Human Error: Mechanical systems provide a reliable barrier against mistakes, which are often the leading cause of pipeline accidents.

-

Long-Term Reliability: Durable materials and fail-safe designs ensure that interlocks provide consistent performance even in challenging environments.

Nudango's Role in Advancing Pipeline Safety

Nudango has established itself as a trusted partner in industrial safety solutions. With a strong reputation in the industry, the company provides a comprehensive range of products designed for pipeline safety. From valve interlocks and trapped key systems to remote and portable actuators, Nudango delivers solutions that combine reliability, ease of use, and compliance with international standards. Its expertise spans multiple industries, including petrochemical, electric power, steel, shipbuilding, and ocean engineering, demonstrating the versatility and effectiveness of its safety products.

Conclusion

Mechanical valve interlocks are an essential component of pipeline safety, providing physical assurance that operational protocols are followed. When selecting and implementing interlocks, considerations such as compliance, system design, material suitability, ease of operation, integration, redundancy, and training are critical for success.

By leveraging advanced interlock systems from experienced providers like Nudango, industries can enhance operational safety, minimize human error, and ensure the long-term reliability of pipeline networks. As industrial processes become increasingly complex, the role of mechanical valve interlocks will continue to grow, offering an indispensable safeguard for critical infrastructure around the world

www.nudango.com

nudango

More Stories

Mastering Elevator Efficiency: A Deep Dive into the Functionality of Elevator Controllers

How Solar Home Batteries Can Reduce Your Electricity Bills and Increase Energy Independence

A Complete Guide to Choosing the Right Process Waste Incinerator for Your Facility