The women's wool collarless overcoat is a timeless piece of clothing that has been a staple in women's wardrobes for decades. Known for its elegance and versatility, this garment is crafted with precision and attention to detail. In this blog post, QD Apparel will share the manufacturing process of women's wool collarless overcoat for sale, from material selection to the final finishing touches.

Material Selection

The first step in the manufacturing process is the selection of materials. For a high-quality wool collarless overcoat, the fabric must be of the utmost importance. Wool is chosen for its warmth, durability, and natural water-resistant properties. The type of wool can vary, with options including merino, cashmere, or a blend with synthetic fibers for added strength and ease of care.

1. Fiber Sourcing: The sourcing of wool fiber is the first step in the manufacturing process. The type of wool can vary, including merino, cashmere, or blended with synthetic fibers for added strength and easy care.

2. Fabric Weaving: Once the wool has been sourced, it is spun into yarn and woven into fabric. The weave can be plain, twill, or even a more complex pattern depending on the desired look and feel of the overcoat.

Design and Pattern Making

Before the actual production begins, the design of the overcoat must be finalized, and patterns are created.

1. Design Conceptualization: Designers sketch out the overcoat, considering factors such as style, fit, and functionality. This includes deciding on collarless design elements, pocket placements, and any other unique features.

2. Pattern Creation: Based on the design, a pattern is created. This involves translating the two-dimensional sketch into a set of patterns that can be laid out on the fabric for cutting.

Cutting and Preparation

With the patterns ready, the next step is to cut the fabric into the necessary pieces for assembly.

1. Fabric Inspection: Before cutting, the fabric is inspected for any defects or inconsistencies to ensure the quality of the final product.

2. Cutting: Using large cutting tables and precision cutting tools, the fabric is cut according to the patterns. This step requires extreme accuracy to ensure that all pieces fit together correctly.

Assembly and Sewing

The assembly process involves sewing the various pieces of the overcoat together.

1. Seam Construction: Seams are created by sewing together the edges of the fabric pieces. This can be done by hand or machine, depending on the desired finish and the complexity of the seam.

2. Interlining Attachment: For added structure and to maintain the shape of the overcoat, an interlining fabric is attached to the main fabric. This is typically done before the main assembly to ensure a smooth finish.

3. Garment Assembly: The main body of the overcoat is assembled, with the front pieces, back pieces, and sleeves being sewn together. Special attention is given to the collarless design, ensuring a clean and polished finish around the neckline.

4. Pocket and Detail Assembly: Pockets and other details are added at this stage. This includes the insertion of lining, which is sewn into the overcoat to provide a smooth interior and additional warmth.

Finishing Touches

Once the main assembly is complete, the overcoat undergoes a series of finishing processes.

1. Pressing: The overcoat is pressed to remove any wrinkles and to give the seams a sharp, professional look.

2. Edge Finishing: The raw edges of the fabric, such as the hem and vent openings, are finished. This can be done by folding the edge under and sewing it down, or by applying a binding.

3. Buttonholes and Buttons: Buttonholes are cut and finished, and buttons are sewn on. For a collarless overcoat, this may include a single row of buttons down the front or decorative buttons at strategic points.

4. Quality Control: Each overcoat is inspected for any defects in sewing, fabric, or overall construction. Any issues are corrected before the garment is deemed complete.

5. Final Pressing and Steaming: The overcoat is given a final press to ensure a crisp, professional finish. Steaming is used to relax the fabric and give it a natural drape.

Packaging and Distribution

The final step in the manufacturing process is packaging the overcoat for distribution.

1. Folding and Wrapping: The overcoat is carefully folded and wrapped in tissue paper to protect it from dust and damage during transport.

2. Labeling and Tagging: Labels and tags are attached, providing information about the fabric content, care instructions, and size.

3. Packaging: The overcoat is placed in a protective bag or box, ready for distribution to retailers or direct to consumers.

Conclusion

The manufacturing process of a women's wool collarless overcoat is a complex and detailed endeavor, requiring skilled craftsmanship and a keen eye for quality. From the selection of the finest wool to the meticulous assembly and finishing touches, each step is crucial in creating a garment that is both stylish and durable. Understanding this process sheds light on the value and care that goes into every women's wool collarless overcoat, making it a worthy investment for any wardrobe.

https://www.qdapparel.com/Manufacturing-process-of-wool-collarless-overcoat-for-women.html

www.qdapparel.com

QD Apparel

More Stories

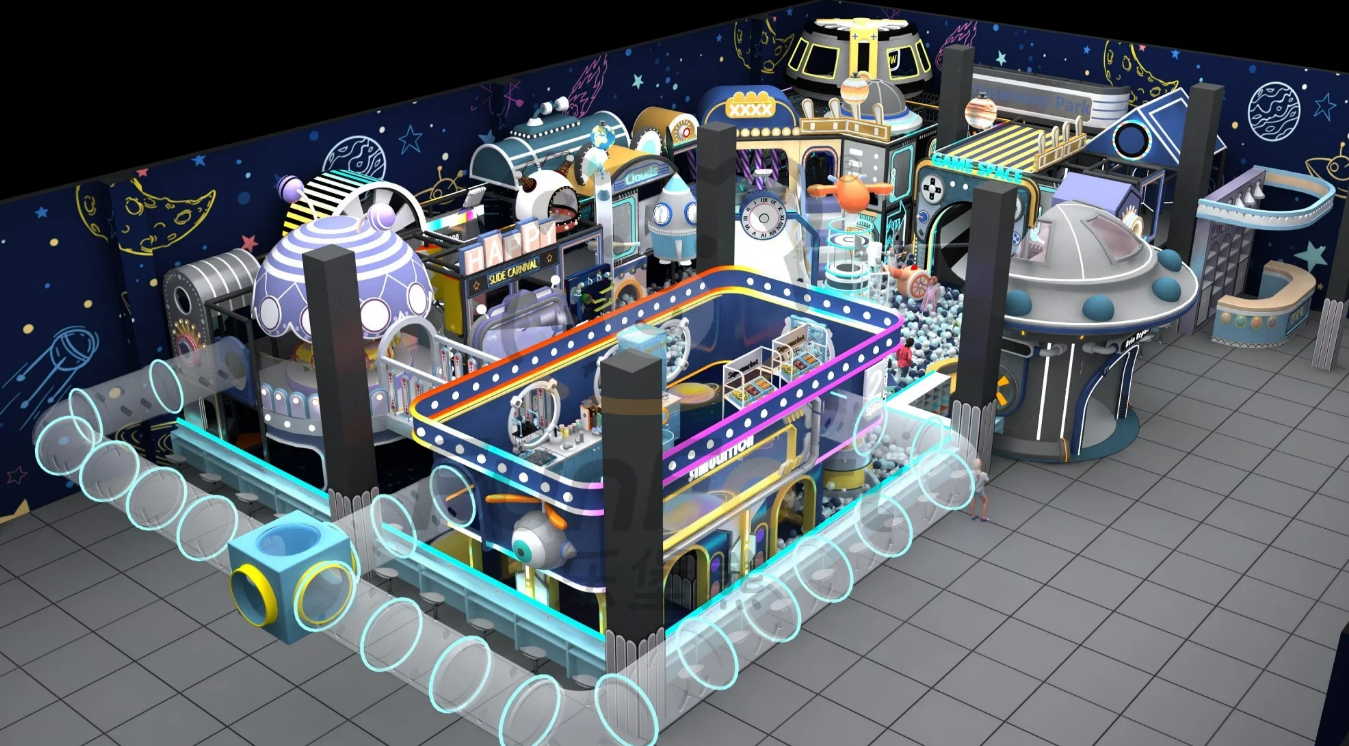

Blast Off Into Fun: Exploring the Magic of a Space-Themed Indoor Playground

https://www.blxflocking.com/korean-velvet.html

Custom Polyester-Cotton Yarn-Dyed Fabric Solutions for Apparel, Home Textiles, and Workwear