In the paper manufacturing industry, safety, efficiency, and precision are critical. The process involves handling various chemicals, high-pressure steam, and water systems, all of which require precise control. One of the most effective tools for ensuring operational safety and preventing human errors is the valve interlock system. Specifically, Nudango’s mechanical-coded valve interlock systems have emerged as a reliable solution for managing manual valves with logical operation sequences.

Understanding Valve Interlock Systems

A valve interlock system is a safety device designed to control the sequence of valve operations. Its purpose is to prevent errors that could lead to process disruption, equipment damage, or even catastrophic accidents. In essence, the system ensures that valves are only operated in a predefined order. This is particularly crucial in industries where the improper opening or closing of valves can cause chemical spills, pipeline overpressure, or cross-contamination of materials.

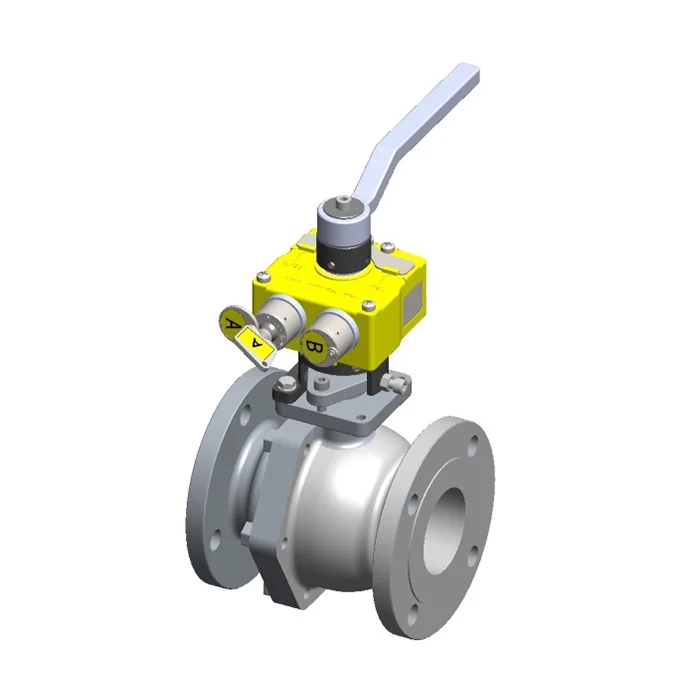

Unlike electronic or pneumatic interlocks, Nudango’s mechanical-coded valve interlocks are designed for manual valve operation. Each interlock incorporates a mechanical coding system that enforces a logical sequence, allowing operators to only move one valve at a time and only in the correct order. This ensures both process safety and operational efficiency.

Importance of Valve Interlocks in the Paper Industry

Paper production is a complex process involving multiple stages, including pulping, bleaching, pressing, and drying. Each stage requires the precise handling of fluids such as water, chemical reagents, and steam. Here’s why valve interlock systems are critical in this context:

-

Preventing Chemical Mixing Errors

Chemicals like chlorine, sodium hydroxide, and hydrogen peroxide are commonly used in pulp bleaching and processing. Accidental mixing of these chemicals can result in hazardous reactions. Mechanical valve interlocks ensure that valves controlling chemical inputs cannot be opened out of sequence, thus preventing dangerous interactions. -

Maintaining Process Continuity

Water and steam systems are integral to pulp preparation, paper pressing, and drying. If a valve is operated incorrectly, it could disrupt flow balance, cause pressure spikes, or interrupt the supply of critical utilities. Valve interlocks guarantee that operators follow the correct sequence, ensuring uninterrupted process continuity. -

Enhancing Operator Safety

Manual valve operation carries inherent risks, especially when dealing with high-temperature steam or corrosive chemicals. By physically restricting improper valve movement, mechanical-coded interlocks protect operators from accidental exposure or injury. -

Reducing Equipment Wear and Tear

Improper valve operation can cause sudden pressure changes, water hammer, or overloading of pumps. Over time, this damages valves, pipes, and associated equipment. Mechanical interlocks enforce correct operation, reducing mechanical stress and extending equipment lifespan.

Nudango’s Mechanical-Coded Valve Interlocks

Nudango’s system is tailored for hand-operated valves, making it particularly suitable for the paper industry, where many critical valves remain manual for operational flexibility. The system functions based on mechanical coding that defines the allowable sequence for each valve. Here’s how it works:

-

Logical Operation Sequence: Each valve is assigned a unique code, which interacts with other valves in the system. The code ensures that only certain valves can be turned at specific times, preventing out-of-sequence operations.

-

Physical Restriction: Unlike electronic systems, Nudango’s mechanical interlocks physically block incorrect movements. Operators cannot bypass the system, ensuring absolute compliance with safety protocols.

-

Customizable Logic: The mechanical coding can be configured to match the specific process requirements of a paper mill, whether controlling chemical dosing, steam supply, or water flow.

By combining physical security with logical operation rules, Nudango’s system minimizes human error without relying on electronic sensors or control systems, which might fail due to power outages or software glitches.

Key Applications in the Paper Industry

-

Pulping and Chemical Processing Lines

In pulping, chemical agents are added to break down raw wood fibers. Mechanical valve interlocks ensure that chemicals are added in the correct sequence, preventing reactions that could compromise pulp quality or cause dangerous conditions. -

Bleaching Operations

The bleaching stage often uses multiple chemical solutions applied in a precise order. Valve interlocks prevent operators from opening valves simultaneously or in the wrong order, safeguarding both the product and personnel. -

Steam and Water Distribution Systems

Paper mills rely heavily on steam for drying and water for fiber processing. Interlocks ensure valves for steam and water lines operate in a safe sequence, preventing overpressure and ensuring balanced flow distribution across multiple machines. -

Recovery and Recycling Systems

Modern paper mills incorporate chemical recovery and water recycling systems to reduce waste and costs. These systems often have complex piping with numerous valves. Mechanical-coded interlocks guide operators to operate valves correctly, avoiding contamination between recycled and fresh streams.

Benefits of Mechanical-Coded Valve Interlocks in Paper Mills

-

Improved Safety: Reduces the risk of chemical accidents, steam burns, and operator errors.

-

Operational Efficiency: Ensures that processes run smoothly without unplanned interruptions.

-

Cost Savings: Minimizes equipment damage, reduces chemical wastage, and prevents costly downtime.

-

Reliability: Mechanical interlocks are durable and resistant to environmental factors such as moisture, temperature changes, and dust—common in paper mills.

-

Compliance: Helps meet industrial safety standards and regulatory requirements for chemical handling and process safety.

Implementation Considerations

When integrating mechanical valve interlock systems in a paper mill, several factors should be considered:

-

Process Mapping: Identify critical valves and define their operational sequence to design the interlock logic.

-

Operator Training: Even with interlocks, operators must understand the system and follow standard operating procedures.

-

Maintenance: Mechanical systems require periodic inspection to ensure smooth operation and prevent wear from compromising interlock function.

-

Customization: Each paper mill has unique processes; the interlock logic should be tailored to match specific workflow requirements.

Conclusion

Valve interlock systems, especially Nudango’s mechanical-coded systems for manual valves, play a crucial role in the paper industry. They provide a robust solution for ensuring safety, maintaining operational continuity, and protecting both personnel and equipment. By enforcing logical sequences and preventing incorrect valve operations, these systems reduce human error and enhance process reliability.

In an industry where chemical handling, high-pressure steam, and water systems intersect, mechanical valve interlocks are more than a convenience—they are a necessity. Implementing Nudango’s system allows paper mills to operate efficiently, safely, and sustainably, making it an indispensable component of modern paper production.

www.nudango.com

nudango

More Stories

Stainless Steel Ball Valves vs. Brass Valves: Which One is Better?

Comparing Different Types of Elevator Traction Systems

How Electric Vehicles Are Driving Demand for Automotive Body Adhesives