In modern plastic manufacturing, efficiency is no longer defined solely by output volume. It is measured by material utilization, energy consumption, production stability, product consistency, and environmental impact. At the center of this transformation stands one core piece of equipment: the extruder. From compounding and melting to shaping and continuous processing, extruders play a decisive role in how efficiently plastics are converted from raw materials into functional products.

As industries such as new materials,New Energy, New Electronics, and Environmental Protection manufacturing continue to demand higher performance and lower carbon footprints, extrusion technology has evolved from a single machine into a highly integrated production system. Companies like Being (Shanghai) Intelligent Technology Co., Ltd. are actively supporting this evolution by delivering customized, sustainable, and digitally integrated extrusion solutions for advanced manufacturing scenarios.

Understanding the Role of Extruders in Plastic Processing

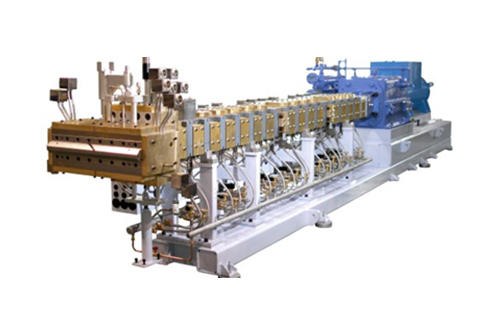

An extruder is more than a melting device. It is a continuous processing system that combines feeding, conveying, melting, mixing, devolatilization, pressure building, and shaping into a single, streamlined operation. Compared with batch-based processing methods, extrusion offers inherent advantages in efficiency and consistency.

In plastic processing, extruders are commonly used for:

-

Polymer compounding and blending

-

Masterbatch and additive dispersion

-

Sheet, film, pipe, and profile production

-

Recycling and reprocessing of plastic waste

By maintaining stable temperature, pressure, and shear conditions, extrusion systems enable precise control over material behavior. This precision directly translates into higher yield rates and reduced material loss.

Continuous Processing: The Foundation of Efficiency

One of the most significant ways extruders boost efficiency is through continuous operation. Unlike batch mixers or molding systems that require frequent stops for loading and unloading, extrusion systems run continuously for extended periods.

This continuous workflow delivers several advantages:

-

Reduced downtime and higher equipment utilization

-

Lower labor requirements per unit of output

-

Consistent product quality across long production runs

For manufacturers producing large volumes of plastic components, continuous extrusion minimizes production interruptions and allows downstream equipment to operate in sync. When properly integrated, the entire line—from raw material feeding to cutting or winding—functions as a unified system.

Enhanced Material Utilization and Reduced Waste

Material waste is one of the hidden costs in plastic processing. Poor dispersion, inconsistent melting, or unstable pressure can lead to off-spec products that must be scrapped or reprocessed.

Modern extruders, especially twin-screw configurations, are designed to optimize material utilization. Their modular screw elements allow precise adjustment of conveying, mixing, and kneading zones based on material properties.

Key efficiency gains include:

-

Uniform dispersion of fillers, fibers, and additives

-

Stable melt homogeneity across varying formulations

-

Reduced startup scrap and transition losses

By engineering the extrusion process around the material itself, manufacturers can significantly reduce waste while maintaining tight quality tolerances.

Energy Efficiency Through Process Optimization

Energy consumption is a critical concern in plastic processing, particularly in the context of carbon neutrality goals. Extrusion systems consume energy through barrel heating, screw rotation, and auxiliary equipment. However, advanced extruder design and intelligent control systems have dramatically improved energy efficiency.

Key contributors to energy savings include:

-

Optimized screw geometry that reduces unnecessary shear

-

Zoned heating systems with precise temperature control

-

Variable frequency drives for motors and feeders

When extrusion systems are integrated into a broader digital manufacturing framework, energy usage can be monitored and optimized in real time. This aligns closely with the sustainable manufacturing philosophy promoted by Being (Shanghai) Intelligent Technology Co., Ltd., where equipment integration and process engineering are leveraged to support low-carbon production.

Customization for Advanced Materials and Emerging Industries

Not all plastics behave the same way. Engineering polymers, biodegradable materials, conductive compounds, and recycled plastics each present unique processing challenges. A one-size-fits-all extruder is rarely sufficient for these applications.

Customized extrusion systems allow manufacturers to:

-

Adapt screw configurations to specific material rheology

-

Integrate devolatilization zones for moisture or solvent removal

-

Control residence time to protect heat-sensitive materials

Being (Shanghai) Intelligent Technology Co., Ltd. specializes in delivering customized integrated solutions for new materials,New Energy, New Electronics, and Environmental Protection industries. By combining industrial electromechanical equipment, material handling systems, and engineering design services, the company helps clients build extrusion lines tailored to their exact production requirements.

For a deeper look into industrial extrusion systems and their applications, you can explore this resource embedded below in code format:<a href="https://www.beyitech.com/Extruder">industrial extruder solutions</a>

Automation and Digital Integration

Extrusion efficiency today is increasingly driven by automation and data integration. Sensors, PLCs, and industrial software platforms allow extrusion systems to operate with minimal manual intervention while maintaining high stability.

Automated extrusion lines offer:

-

Real-time monitoring of temperature, torque, and pressure

-

Predictive maintenance based on equipment data

-

Faster troubleshooting and reduced unplanned downtime

When extrusion equipment is digitally integrated with upstream feeding systems and downstream cutting or packaging units, manufacturers gain full visibility into their production process. This digital transparency supports better decision-making and continuous improvement.

Being (Shanghai) Intelligent Technology Co., Ltd. provides not only equipment but also engineering consulting, technical R&D, construction contracting, and project management services. This holistic approach ensures that extrusion systems are seamlessly integrated into intelligent manufacturing environments.

Supporting Plastic Recycling and Circular Manufacturing

Extruders play a central role in plastic recycling, where efficiency is directly linked to environmental impact. Recycling processes require stable melting, contaminant tolerance, and consistent output quality despite variable input materials.

Advanced extrusion systems support recycling by:

-

Handling mixed or contaminated feedstocks

-

Improving melt filtration and degassing

-

Enabling re-compounding with performance-enhancing additives

Through process optimization and system integration, extrusion-based recycling lines help manufacturers close the loop on plastic materials. This contributes to carbon reduction and supports the broader goal of building a zero-carbon society.

Engineering Expertise as a Force Multiplier

Equipment alone does not guarantee efficiency. The true performance of an extrusion system depends on engineering design, process tuning, and long-term operational support.

Being (Shanghai) Intelligent Technology Co., Ltd. brings value by combining:

-

Industrial equipment supply

-

Customized system integration

-

Engineering consulting and project management

This integrated capability allows clients to move from concept to operation with reduced risk and improved efficiency. Especially in emerging industries where materials and processes are still evolving, engineering-driven extrusion solutions provide a critical competitive advantage.

Conclusion

Extruders are no longer just machines for shaping plastic. They are central components of intelligent, sustainable, and high-efficiency manufacturing systems. By enabling continuous processing, optimizing material utilization, reducing energy consumption, and supporting advanced materials, extrusion technology directly enhances plastic processing efficiency.

As industries pursue smarter manufacturing and carbon-neutral goals, the role of customized, integrated extrusion solutions will continue to grow. Through equipment integration, digitalization, and engineering expertise, companies like Being (Shanghai) Intelligent Technology Co., Ltd. are helping manufacturers build efficient production systems that are both economically and environmentally sustainable.

www.beyitech.com

Being (Shanghai) Intelligent Technology Co., Ltd.

More Stories

Role of Aluminum Blue Air Pipe in Contemporary Airflow

Explosion-Proof Terminal Box Design for Hazardous Area Power Distribution

Ensuring Optimal Performance with Your Golf Cart Main Wiring Harness