When it comes to fluid dynamics and gas management systems, the placement of pressure gauges in relation to regulators is a topic that often sparks debate among engineers and technicians. Understanding whether the pressure gauge should be installed before or after the regulator is crucial for ensuring system efficiency, safety, and accuracy in pressure readings. This article delves into the intricacies of pressure gauge placement, exploring the implications of each configuration and providing practical guidance for optimal setup.

Understanding the Basics: Pressure Gauges and Regulators

Before diving into the specifics of placement, it’s essential to clarify the roles of pressure gauges and regulators. A pressure gauge is an instrument used to measure the pressure of a fluid or gas within a system, providing critical data for monitoring and control. A regulator, on the other hand, is designed to maintain a consistent output pressure regardless of fluctuations in the input pressure, ensuring that downstream equipment operates within safe and efficient parameters.

The Case for Placing the Pressure Gauge Before the Regulator

- Monitoring Input Pressure: Installing the pressure gauge before the regulator allows for real-time monitoring of the input pressure. This is particularly important in systems where the source pressure can fluctuate significantly. By observing the input pressure, operators can identify potential issues such as pressure spikes or drops that could affect the performance of the regulator.

- System Diagnostics: A pre-regulator gauge can serve as a diagnostic tool. If the regulator is not functioning correctly, the gauge will indicate whether the problem lies with the regulator itself or the upstream supply. This can save time and resources during troubleshooting.

- Safety Considerations: In high-pressure applications, having a gauge before the regulator can enhance safety. Operators can quickly assess whether the incoming pressure is within acceptable limits before it reaches the regulator, reducing the risk of over-pressurization and potential equipment failure.

The Case for Placing the Pressure Gauge After the Regulator

- Monitoring Output Pressure: The primary advantage of placing the pressure gauge after the regulator is that it provides a direct measurement of the output pressure delivered to downstream equipment. This is crucial for ensuring that the system operates within the desired pressure range.

- Regulator Performance Assessment: By monitoring the output pressure, operators can evaluate the performance of the regulator. If the output pressure deviates from the set point, it may indicate that the regulator requires adjustment or maintenance.

- Enhanced Control: In applications where precise pressure control is essential, having the gauge after the regulator allows for immediate feedback on the system’s performance. This can facilitate quicker adjustments and improve overall process control.

Factors Influencing Gauge Placement Decisions

While the arguments for both placements are compelling, several factors should be considered when deciding where to install the pressure gauge:

- System Design: The overall design of the system, including the type of fluids or gases being managed, can influence gauge placement. For instance, in a gas distribution system, the pressure dynamics may necessitate a different approach than in a hydraulic system.

- Operational Requirements: The specific operational requirements of the application should guide the decision. For example, if precise output pressure control is critical, placing the gauge after the regulator may be more beneficial.

- Maintenance and Accessibility: Consideration should also be given to maintenance needs. A gauge that is easily accessible for calibration and replacement can minimize downtime and improve system reliability.

Conclusion: Making an Informed Decision

Ultimately, the decision of whether to place the pressure gauge before or after the regulator is not a one-size-fits-all answer. It requires a careful assessment of the system’s design, operational needs, and safety considerations. By understanding the implications of each placement option, engineers and technicians can make informed decisions that enhance system performance and reliability.

More Stories

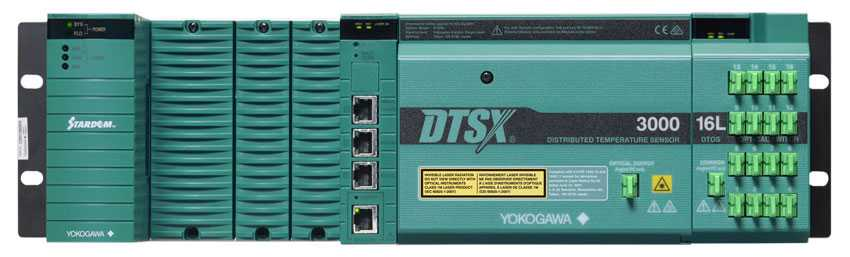

Exploring the Advantages of Real-time Temperature Monitoring with DTS

Stainless Steel Ball Valves vs. Brass Valves: Which One is Better?

Comparing Different Types of Elevator Traction Systems