Mechanical relays are essential components in various industries, providing reliable switching and control functions. However, understanding the lifespan of these relays is crucial for optimizing their usage and ensuring uninterrupted operations. In this article, we will delve into the factors that influence the longevity of mechanical relays, shedding light on their expected lifespan and offering practical tips for extending their service life.

- The Basics of Mechanical Relays:

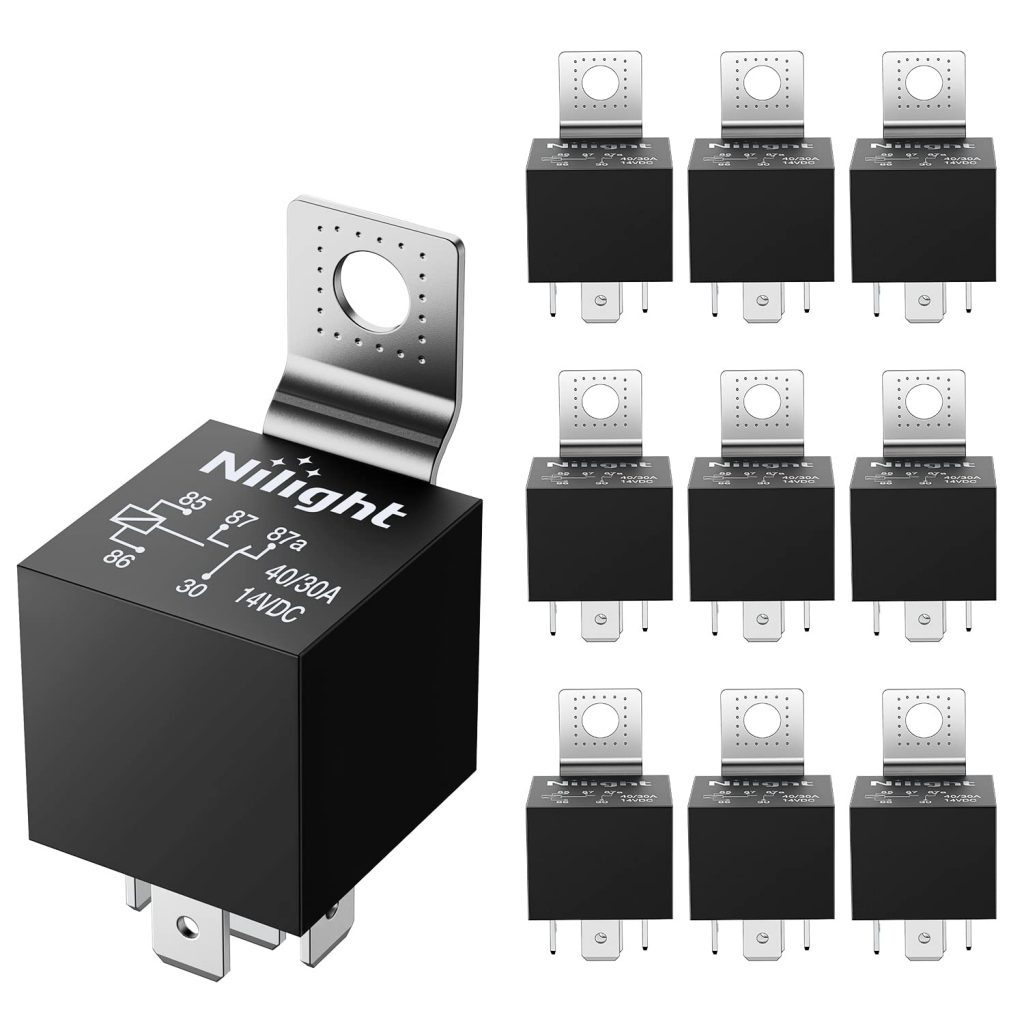

Before exploring the lifespan of mechanical relays, let's first establish a foundational understanding of their construction and operation. Mechanical relays consist of several key components, including an electromagnet, contacts, and a spring mechanism. When an electrical current flows through the coil, it generates a magnetic field that attracts the contacts, closing the circuit and allowing the current to flow. This mechanical action is repeated each time the relay is activated or deactivated. - Factors Affecting Relay Lifespan:

a) Electrical Load: The electrical load placed on a mechanical relay significantly impacts its lifespan. Higher currents and voltages can cause increased wear and tear on the contacts, leading to a shorter lifespan. It is crucial to carefully consider the relay's specifications and ensure it is appropriately rated for the intended load.

b) Switching Frequency: The frequency at which a relay is switched on and off also affects its longevity. Frequent switching can accelerate contact erosion and mechanical fatigue, reducing the relay's lifespan. Optimal relay selection and proper load management can help mitigate this issue.

c) Environmental Conditions: Mechanical relays are susceptible to environmental factors such as temperature, humidity, and vibration. Extreme temperatures can cause thermal expansion and contraction, leading to premature failure. Additionally, high humidity levels and excessive vibration can compromise the relay's performance and lifespan. Implementing suitable protective measures, such as enclosures and temperature control systems, can help mitigate these risks.

d) Contact Material and Design: The choice of contact material and design significantly impacts the relay's lifespan. Materials with high resistance to wear, corrosion, and oxidation, such as silver or gold-plated contacts, tend to offer longer lifespans. Additionally, the design of the contacts, including their shape and surface area, can influence their durability and resistance to arcing.

- Expected Lifespan of Mechanical Relays:

The average lifespan of mechanical relays can vary depending on the aforementioned factors. Generally, mechanical relays can last anywhere from 100,000 to 1,000,000 operations. However, with proper selection, maintenance, and operating conditions, some relays have been known to exceed these figures and provide reliable performance for even longer periods. - Extending Relay Lifespan:

To maximize the lifespan of mechanical relays, consider the following tips:

a) Proper Load Management: Ensure the relay is appropriately rated for the electrical load it will handle. Avoid overloading the relay to prevent excessive wear on the contacts.

b) Regular Maintenance: Periodically inspect and clean the relay contacts to remove any debris or oxidation that may affect their performance. Additionally, lubricating the moving parts can help reduce friction and extend the relay's lifespan.

c) Environmental Control: Maintain suitable environmental conditions, including temperature and humidity levels, to minimize the impact of external factors on the relay's performance.

d) Surge Protection: Implement surge protection devices to safeguard the relay against voltage spikes and transient currents, which can cause premature failure.

Conclusion:

Understanding the lifespan of mechanical relays is crucial for optimizing their usage and ensuring reliable operations. By considering factors such as electrical load, switching frequency, environmental conditions, and contact material/design, one can extend the relay's lifespan and minimize the risk of unexpected failures. Implementing proper load management, regular maintenance, environmental control, and surge protection measures will contribute to the longevity and reliability of mechanical relays in various applications.

More Stories

What Is Multistage Centrifugal Pump and How Does It Work

Large Steel Silos for Grain Storage in Global Supply Chains

Thermal Interface Material Applications in High-Performance Server Chips: Overcoming Material Obstacles for Kilowatt-Level Heat Flux