Polypropylene (PP) is a widely used thermoplastic in industries such as packaging, automotive, construction, and consumer goods. To recycle and reuse PP efficiently, manufacturers often rely on disc type PP grinders—machines that pulverize PP materials into fine powder or granules for further processing. Choosing the right grinder is crucial for achieving optimal output quality, energy efficiency, and long-term cost savings.

In this article, we’ll explore what a disc type PP grinder is, key factors to consider when selecting one, and how trusted manufacturers like Wuxi Songhu Xinrui Machinery Co., Ltd., a professional producer of PE milling machines and PVC crushing equipment, deliver reliable solutions to meet diverse customer needs.

1. Understanding Disc Type PP Grinders

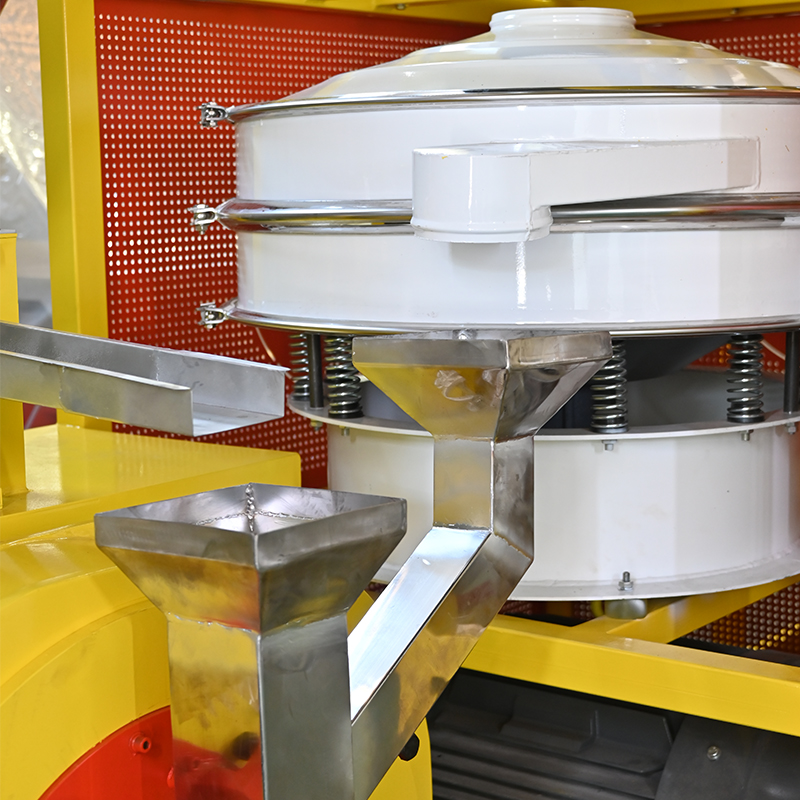

A disc type PP grinder uses two rotating discs to grind PP materials into uniform powder. The process typically involves:

Feeding – Raw PP material enters the machine through a hopper.

Grinding – Rotating discs apply shear and impact forces to break down the material.

Separation – Fine powder passes through a mesh screen, while larger particles return for regrinding.

These grinders are known for:

High efficiency – Capable of producing fine, consistent powder.

Compact design – Easy to integrate into existing production lines.

Versatility – Suitable for PP as well as other thermoplastics with similar hardness.

2. Key Factors to Consider When Choosing a Disc Type PP Grinder

a) Capacity and Output

The right capacity depends on your production requirements.

Small-scale operations may only need a grinder capable of processing 50–100 kg/h.

Industrial-scale plants may require machines that handle 500 kg/h or more.

Wuxi Songhu Xinrui Machinery Co., Ltd. offers grinders in multiple capacity ranges, ensuring you can scale without sacrificing performance.

b) Grinding Fineness

The particle size of the final powder affects its usability.

Fine powders are ideal for film, sheet, and coating applications.

Coarser powders may be used for injection molding or extrusion.

Advanced machines from Wuxi Songhu Xinrui feature adjustable disc spacing, allowing precise control over fineness.

c) Energy Efficiency

Energy consumption impacts operating costs.

Look for models with optimized motor design and low-friction bearings.

Machines with temperature control systems prevent material melting, reducing waste and energy use.

d) Build Quality and Durability

The grinder’s components, especially the discs, should be made from high-strength, wear-resistant materials.

Hardened steel or alloy discs prolong service life.

Rigid machine frames minimize vibration, improving grinding precision.

Wuxi Songhu Xinrui machines are built with robust materials and precision engineering, reducing maintenance needs.

e) Ease of Maintenance

Quick access to the grinding chamber and easy disc replacement save downtime.

Tool-free opening designs can speed up cleaning.

Machines with modular components simplify servicing.

f) Safety Features

Safety should be a priority, especially in high-speed grinding operations.

Emergency stop buttons

Overload protection systems

Safety interlocks to prevent operation when covers are open

3. Applications of Disc Type PP Grinders

Disc type PP grinders are used in:

Plastic recycling plants – Turning scrap PP into reusable powder.

Plastic manufacturing – Preparing material for extrusion, injection molding, or blow molding.

Packaging industry – Recycling defective products into raw material for new packaging.

With their experience in PE milling and PVC crushing equipment, Wuxi Songhu Xinrui designs grinders that integrate seamlessly into these workflows.

4. Why Choose Wuxi Songhu Xinrui Machinery Co., Ltd.

As a professional manufacturer specializing in PE milling machines and PVC crushers, Wuxi Songhu Xinrui has built a reputation for:

High-performance equipment – Reliable, efficient grinding with consistent output.

Custom solutions – Tailored machines to fit specific production requirements.

Strong after-sales support – Technical guidance, spare parts availability, and maintenance services.

Quality craftsmanship – Precision manufacturing for long-lasting performance.

Conclusion

Selecting the right disc type PP grinder involves evaluating capacity, fineness, energy efficiency, durability, maintenance needs, and safety features. A well-chosen machine can significantly improve productivity, reduce waste, and enhance the quality of recycled PP material.

With proven expertise in plastic grinding and crushing equipment, Wuxi Songhu Xinrui Machinery Co., Ltd. offers robust, customizable solutions that meet the needs of both small-scale recyclers and large industrial producers. By partnering with a trusted manufacturer, you can ensure your PP grinding operations run smoothly, efficiently, and profitably.

Essential Features That Make Disc Type PP Grinders Ideal for Plastic Waste Processing

www.songhuxr.com

Wuxi Songhu Xinrui Machinery Co., Ltd.

More Stories

How CNC Aluminum Machining Supports High-Performance Industrial Applications

Optical Domes for Drone Payload: Enhancing Aerial Imaging and Sensor Protection

Ni·Shangle Gallery Unveils Cutting-Edge Fine Art Printing Technology Benefits and Applications