Introduction

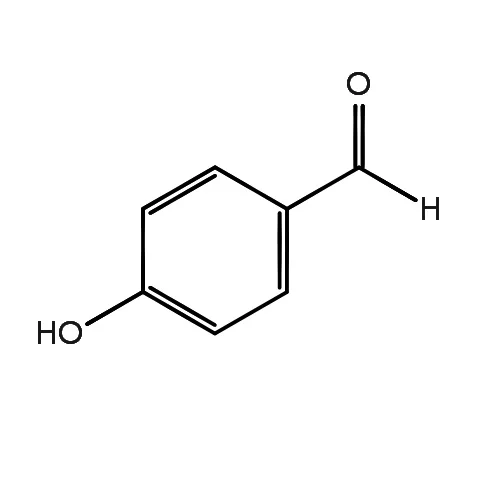

P-Hydroxybenzaldehyde (PHBA, CAS 123-08-0) is a versatile chemical intermediate with wide-ranging applications in pharmaceuticals, herbicides, and specialty chemicals. Its unique molecular structure (C7H6O2) and para-hydroxyl functional group allow it to participate in a variety of organic syntheses with high efficiency. With global demand rising for pharmaceutical intermediates and agrochemical production, PHBA has become an essential component for B2B buyers seeking high-purity, reliable chemical supplies. In this blog post, as high quality pharmaceutical intermediates manufacturer, Kingvolt will share the applications of P-Hydroxybenzaldehyde supply for the global pharmaceutical and specialty chemical markets.

Pharmaceutical Synthesis Driven by P-Hydroxybenzaldehyde

• PHBA is a critical building block in the synthesis of antibiotics such as amoxicillin, enhancing yield and reaction consistency in industrial pharmaceutical processes.

• It is also used to produce antibacterial synergistic agents like TMP (Trimethoprim), which are increasingly important in combating multi-resistant bacterial strains.

• Advanced pharmaceuticals, including farrerol, esmolol hydrochloride, and artificial gastrodia elata derivatives, rely on PHBA for stable and predictable synthesis outcomes.

• According to a 2024 report by Grand View Research, the global pharmaceutical intermediates market is projected to grow at a CAGR of 6.3% from 2024 to 2030, with PHBA ranking among the top intermediates in high-value drug synthesis.

• Its compatibility with various solvents and catalysts makes PHBA particularly suitable for large-scale manufacturing, reducing process variability and ensuring product consistency for international clients.

PHBA as a Core Intermediate in Herbicide Production

• In the agrochemical sector, PHBA is a key precursor for bromoxynil and chloroxynil, widely used broadleaf herbicides that protect crop yields while maintaining regulatory compliance.

• The compound’s high purity and stability are critical for herbicide synthesis, as impurities can significantly reduce efficacy or lead to production inefficiencies.

• Market research indicates that the global herbicide market is expected to exceed USD 35 billion by 2030, with PHBA-based intermediates playing a vital role in supply chains.

• North America and Europe are major consumers of PHBA for herbicide production, while Asia-Pacific is rapidly increasing both production and consumption, highlighting global B2B sourcing opportunities.

Specialty Chemical Applications of P-Hydroxybenzaldehyde

• Beyond pharmaceuticals and herbicides, PHBA contributes to bactericides, photographic emulsifiers, nickel plating luster agents, and liquid crystal materials, demonstrating its multifunctional industrial utility.

• In the flavor and fragrance industry, PHBA is indispensable for synthesizing vanillin, ethyl vanillin, piperonal, springaldehyde, p-anisaldehyde, and natural raspberry ketone. Its ability to serve as a precursor for multiple aroma compounds makes it a high-demand chemical in international specialty markets.

• The global flavor and fragrance market exceeded USD 30 billion in 2024, with intermediates like PHBA playing a key role in meeting both natural and artificial compound production needs.

• Its chemical versatility allows manufacturers to optimize production processes, reduce waste, and maintain compliance with international standards.

Chemical Properties Supporting Industrial Versatility

• PHBA’s molecular weight of 122.12 g/mol and its para-hydroxyl functional group facilitate controlled reactivity in diverse organic syntheses.

• The compound exhibits high thermal stability and solvent compatibility, supporting scalability from laboratory experiments to industrial batch production.

• Predictable reaction mechanisms allow manufacturers to minimize by-products and optimize yields, essential for cost-effective B2B chemical production.

• Its purity consistency ensures downstream synthesis reliability, a critical factor for pharmaceutical intermediates and specialty chemical applications.

Global Supply Dynamics and Market Insights

• North America and Europe are primary markets for PHBA due to their advanced pharmaceutical and specialty chemical sectors, while Asia-Pacific is increasingly important as both a production hub and consumer region.

• International B2B buyers prioritize suppliers that can guarantee CAS-certified, pharmaceutical-grade materials compliant with GMP, REACH, and ISO standards.

• Strategic sourcing decisions often consider supplier capacity, analytical verification capabilities, and adherence to sustainable manufacturing practices.

• Market intelligence suggests that supply chain reliability, combined with technical support, is a key differentiator for PHBA suppliers targeting global B2B clients.

B2B Considerations for Sourcing PHBA

• High purity and batch consistency are critical, particularly for pharmaceutical intermediates where even minor impurities can compromise drug synthesis.

• Analytical verification methods such as HPLC and GC are essential for confirming material quality.

• Efficient logistics and global shipping reliability minimize downtime and ensure continuous production for international buyers.

• Regulatory compliance verification, including REACH and GMP certifications, enhances trust and reduces procurement risk.

Future Opportunities and Industry Outlook

• The demand for high-purity intermediates in pharmaceuticals, agrochemicals, and specialty chemicals is expected to grow steadily, reinforcing PHBA’s strategic importance.

• Emerging applications in electronic materials, such as liquid crystals and photochemical agents, indicate additional market potential beyond traditional chemical sectors.

• Suppliers providing technical support, quality assurance, and regulatory compliance documentation will be well-positioned to secure long-term B2B partnerships.

• The trend toward sustainable chemical production and the use of PHBA in greener synthetic pathways further enhances its relevance for environmentally-conscious buyers.

Conclusion

P-Hydroxybenzaldehyde is an indispensable intermediate for pharmaceuticals, herbicides, and specialty chemicals. Its versatile chemical properties, industrial performance, and global demand make it a strategic asset for B2B buyers seeking reliable, high-purity intermediates. Companies investing in quality assurance, regulatory compliance, and innovative production methods can leverage PHBA to enhance market competitiveness and secure international partnerships.

www.kingvolt.com

Kingvolt

More Stories

Truck Recovery Straps vs Tow Straps: What’s the Difference?

How Aminowill Fermentation Technology Ensures Purity in Pharmaceutical Grade Amino Acid Sourcing

10 Must-Try Activities for Families at Indoor Adventure Parks