Relief printing is a traditional and versatile printing technique that has been used for centuries to create stunning artworks and prints. It involves carving a design into a block or plate, applying ink to the raised surface, and then transferring the image onto paper or another surface. One of the key factors that contribute to the success of relief printing is the choice of materials. In this article, we will delve into the various materials used in relief printing and explore their unique characteristics and applications.

- Wood:

Wood has been a popular choice for relief printing for centuries. It offers a natural and organic texture to the prints, adding depth and character to the artwork. Different types of wood, such as birch, cherry, or maple, can be used depending on the desired effect. Woodblocks are durable and can withstand multiple print runs, making them ideal for large editions. However, woodblocks require careful maintenance to prevent warping or splitting. - Linoleum:

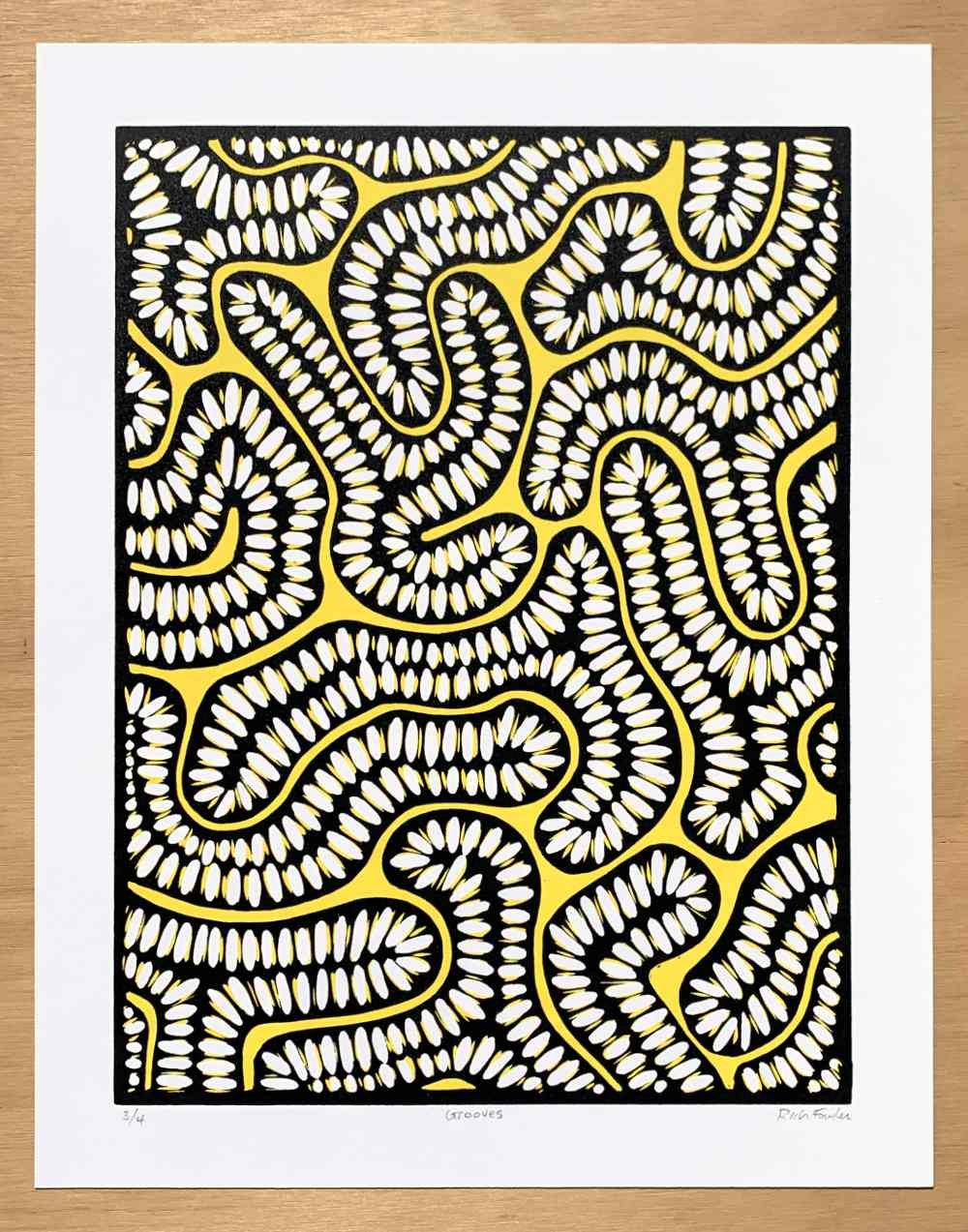

Linoleum, also known as linocut, is a more recent addition to relief printing materials. It is made from a mixture of linseed oil, cork dust, and resins, which are then pressed onto a backing material. Linoleum blocks are softer and easier to carve compared to woodblocks, allowing for finer details and intricate designs. They are also more flexible, making them suitable for printing on curved surfaces. Linocut prints often have a distinctive texture and bold graphic quality. - Metal:

Metal plates, such as copper or zinc, are commonly used in relief printing techniques like etching or engraving. These plates are incised with acid or engraving tools to create the desired design. Metal plates offer precise and intricate details, making them ideal for creating highly detailed prints. They can also withstand heavy pressure during the printing process, resulting in consistent and sharp images. However, metal plates require specialized equipment and techniques for printing. - Synthetic Materials:

In addition to traditional materials, relief printing has also embraced synthetic materials in recent years. Materials like PVC, acrylic, or rubber can be used to create flexible and durable printing blocks. These synthetic materials offer advantages such as easy carving, resistance to warping, and the ability to create unique textures and effects. They are particularly popular among artists experimenting with mixed media and contemporary relief printing techniques.

In conclusion, relief printing utilizes a wide range of materials, each with its own unique characteristics and applications. Wood, linoleum, metal, and synthetic materials all offer different advantages and possibilities for artists and printmakers. Whether you prefer the organic texture of wood, the boldness of linocut, the precision of metal, or the versatility of synthetic materials, relief printing provides endless opportunities for creativity and expression. So, grab your tools and explore the world of relief printing with these diverse materials!

More Stories

Mechanisms of Damping Deadening Rubber Sheets: How They Reduce Vibration and Noise

How SMC Is Manufactured: Process, Materials, and Quality Control

Customizable Logo Pulp Boxes in Kraft and White for Sustainable Food Packaging Solutions