G-COVE Products: Fully Compatible with MAP, VSP, and SCT Technologies – A Perfect Blend of Sustainability and Innovation

In the food packaging industry, extending shelf life while ensuring food safety and quality is a top priority. By combining innovative technologies with eco-friendly materials, G-COVE is redefining the future of food packaging. Our range of sustainable packaging solutions, including Bowl, Clamshell, Food Compartment Trays, Meat Trays , and other eco-conscious options, are fully compatible with three advanced preservation and coating technologies: Modified Atmosphere Packaging (MAP). These solutions provide efficient, sustainable choices for the food industry.

What is Modified Atmosphere Packaging (MAP)?

Modified Atmosphere Packaging (MAP) is a technology that extends the shelf life of food by adjusting the composition of gases (e.g., oxygen, carbon dioxide, and nitrogen) inside the packaging. This process effectively slows down the growth of bacteria and microorganisms, helping preserve food freshness and quality. MAP is widely used for fresh meat, seafood, fruits, vegetables, cheese, and ready-to-eat meals.

Benefits of Combining MAP with G-COVE Products:

-

Extended Shelf Life: Precisely controlled gas mixtures keep food fresh without the need for chemical preservatives.

-

Versatile Compatibility: G-COVE’s trays and packaging solutions support a wide range of food types, from fresh produce to prepared meals.

-

Eco-Friendly Materials: Made from biodegradable bamboo fiber, our products align with global sustainability goals.

What is Vacuum Seal Packaging (VSP)?

Vacuum Seal Packaging (VSP) removes oxygen from the packaging to create an anaerobic environment that inhibits the growth of bacteria and mold. It also protects food from dehydration and freezer burn, making it ideal for high-protein foods like meat and fish, as well as ready-made meals.

Benefits of Combining VSP with G-COVE Products:

-

Enhanced Freshness: Reduces exposure to oxygen, maintaining the taste, texture, and quality of food.

-

Minimized Waste: Extends shelf life, helping to reduce food waste.

-

Strong Compatibility: G-COVE’s packaging is designed to withstand the pressure of VSP processes while maintaining its eco-friendly properties.

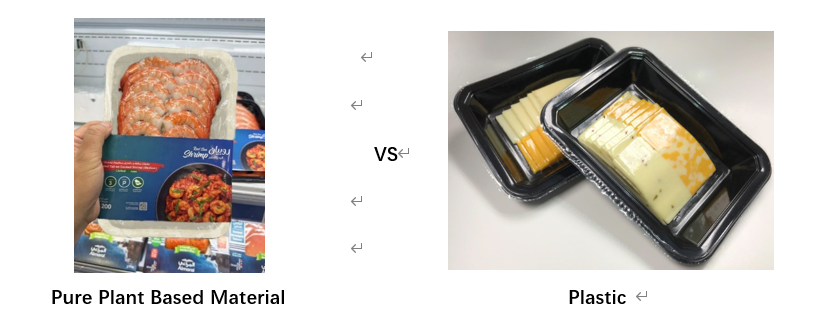

Plastic-Free Design: A Step Toward Sustainable Recycling

One of the most innovative aspects of combining G-COVE’s products with MAP and VSP technologies is the ability to remove the plastic liner from the packaging. This advancement simplifies the separation of plastic and fiber materials, making it easier to recycle or dispose of them through composting. By eliminating the need for a plastic liner, G-COVE provides a more sustainable solution for food packaging, aligning with global efforts to reduce waste and promote circular economies.

www.g-cove.com

G-COVE

More Stories

How SBR Rubber Sheets Are Manufactured: From Compounding to Vulcanization

Exploring New Chapters of Development Together! Shuifa Singyes New Materials Participates in C-Touch & Display Shenzhen 2025 and Commercial Display

How to Choosing the Best Cylinder Essential Oil Packaging Box for Your Brand